Accident prevention features are critical for vehicle safety, comprising advanced airbags, seatbelts, braking systems, and electronic stability control. Regular maintenance, including tasks like fluid replacements and brake inspections, is vital to ensure these features operate optimally and enhance stopping distance/handling. Paintless dent repair not only restores vehicles but also maintains structural integrity and resale value. Robust maintenance programs in automotive body shops, with structured scheduling, staff training, standardized procedures, and continuous improvement, significantly reduce incident likelihood, fostering safer driving and work environments.

Accident prevention is a cornerstone of any safe and efficient operation. Understanding and implementing accident prevention features is essential to mitigate risks and ensure smooth operations. This article delves into the critical role of routine maintenance in enhancing the reliability and performance of safety-focused systems. We explore key components, best practices, and practical strategies for organizations to minimize accidents through proactive maintenance programs, ultimately fostering a safer environment.

- Understanding Accident Prevention Features: Essential Components for Safety

- The Role of Routine Maintenance in Enhancing Reliability and Performance

- Best Practices for Implementing Effective Maintenance Programs to Minimize Accidents

Understanding Accident Prevention Features: Essential Components for Safety

Accident prevention features are integral to any vehicle’s safety system, designed to mitigate risks and protect occupants in the event of a collision. These features encompass a wide array of technologies and mechanisms, from advanced airbags and seatbelts to sophisticated braking systems and electronic stability control. Understanding these components is crucial for several reasons, not least of which is their ability to significantly reduce the likelihood and severity of accidents.

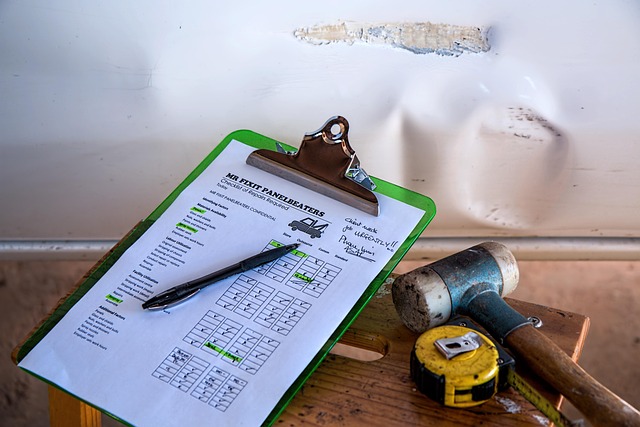

Each element plays a specific role in enhancing safety. For instance, paintless dent repair techniques, often utilized by collision repair centers, can restore vehicles to their pre-accident condition, maintaining structural integrity. Similarly, car paint services that employ modern repairs methods contribute to the overall aesthetics and resale value of the vehicle. Ultimately, these measures not only preserve the financial investment but also ensure the safety features remain effective, thereby fostering a safer driving environment.

The Role of Routine Maintenance in Enhancing Reliability and Performance

Routine maintenance plays a pivotal role in enhancing the reliability and performance of vehicles, thereby significantly contributing to accident prevention features. Regular checks and services ensure that every component of a vehicle functions optimally, reducing the risk of breakdowns or malfunctions that could lead to accidents. For instance, timely fluid replacements, brake system inspections, and tire pressure adjustments can make a world of difference in a car’s stopping distance and overall handling, thus improving safety on the road.

In the realm of accident prevention features, maintaining vehicles in top condition is akin to sharpening a tool before use. Just as a well-maintained machine operates more efficiently, a well-kept vehicle responds quicker to driver inputs, allowing for more precise maneuvering and faster reaction times. This is where car repair services come into play, offering specialized solutions like paintless dent repair to restore vehicles to their original condition, further enhancing both aesthetics and performance, ultimately making our roads safer for everyone.

Best Practices for Implementing Effective Maintenance Programs to Minimize Accidents

Implementing effective maintenance programs is a cornerstone of accident prevention features in any industrial setting, including automotive body shops and vehicle restoration facilities. Best practices involve integrating structured scheduling for regular inspections and servicing, ensuring all staff are trained to recognize potential hazards and report them promptly. Standardized procedures for equipment upkeep and safety checks should be diligently followed to minimize the risk of breakdowns or malfunctions that could lead to accidents during car body repair processes.

Additionally, fostering a culture of continuous improvement by encouraging feedback from workers who interact closely with machinery can further refine maintenance protocols. Regular audits of existing safety measures and proactive adoption of industry-leading practices in vehicle restoration will not only enhance operational efficiency but significantly reduce the likelihood of incidents, creating a safer work environment for all involved in car body repair.

Routine maintenance is not just a best practice; it’s a cornerstone of modern safety management. By proactively addressing equipment and system reliability, organizations can significantly reduce the risk of accidents involving accident prevention features. Integrating regular maintenance checks into operational workflows fosters a culture of safety, ensuring that critical components function as intended, ultimately safeguarding personnel and operations.